3...-R

Category:

Single row taper roller bearings

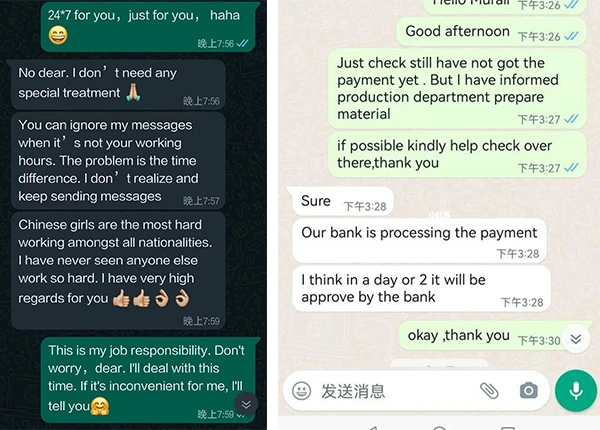

Chat with us now for a quick response.

Keyword:

3...-R

PRODUCT DETAILS

Technical characteristics

Single row taper roller bearings are separablera- dial bearings.

The main dimensions of the metric sized taper ro- ller bearings are standardized by DIN 720(Rolling Bearing -Taper roller bearing)and ISO 355(Ro- lling bearing -Tapered roller bearing -

Boundary dimensions and series designations).

They consist of the inner ring with roller set and cage assembly,(i.e.namely the cone),and a loo- se outer ring(i.e.namely the cup).

In the single row taper roller Bearings when a pure radialloadisplaced on the bearing,it is ge- nerated a load in axial direction,so they must be mounted against another bearing that supports

the axial loads generated.Thus,these bearings are generally mounted in pairs,opposite each other.

Taper roller bearings are suitable for both radial and thrust forces in only one direction but also accept combined loads.

Taper roller bearings transfer the loadsactingon the bearing at a certainangle,it is called contact angle (see Fig.1).

The ability of taper roller bearings to accommo- date axial loads depends on their contact angle. The higher the angle the better the thrust load capability.

The contact angle of most taper roller bearings lies between 10°and 16° .

Taper roller bearings of the series 313 are parti- cularly adequate due to their comparatively large contact angle(approximate 30°),when high axial forces are to be considered.

VEO inch sizes taper roller bearings include the most common sizes of bearings according to the ANSI /ABMA19.2-1994.

The technical characteristics of inch sized taper roller bearings equal to those of metric taper roller bearings.However,inch sized taper roller bearings also have different tolerances than

me- tric sizes.

Even when you can have VEO taper roller bearings in metric and inch series,for new designs they will be preferred metric series.

Standard design variants

VEO produces single row taper roller bearings in several design variants,(e.g.with cage carburi- sed bearing rings or with flanges on outer rings) on customer request ororder.

Misalignment

Misalignments not exceeding 1,5 angular minu- tes (0°,1.5')from their centre position,usually, do not affect negatively the correct operation of single row taper roller bearings.

But it must be considered that taper roller bea-rings which run misaligned are subjected to con-siderable additional forces that will shorten their service life and generate high running noise

le-vels.

Tolerances

VEO taper roller bearings are produced to toleran- ce class PN asstandard.

VEO bearings can be produced with closer toleran- ces according to customer requirements.

VEO inch sized taper roller bearings are produced as standard in normal tolerance as defined by ANSI/ABMA.

Width toleranceand radial run out values of the VEO inch sized taper roller bearings correspond to the values of VEO taper roller bearings in normal tolerance (class PN)according to DIN620-2.

Inch sized taper roller bearings have bigger to- lerances for their bore and outer diameter tole- rances.

Cages

VEOtaper roller bearings are fitted with pressed steel cages as standard.

Because the cages of taper roller bearings usua- lly protrude beyond the bearing faces,special care must betaken to followthe recommended abutment dimensions.

Internal clearance

The axial clearance of taper roller bearings is achieved during mounting by adjusting one bea- ring against another.

The changes in the shaft length,(e.g.caused by thermal expansion),leads into changes in ope- rating clearance.For this reason the distance between bearing positions should be kept to a

minimum.

Minimum load

For effective operation of taper roller bearings a minimum bearing load of approximately 2 per cent of the dynamic load rating Cr is required.

In the case of single row taper rolling bearings of series 320,302,303,322 and 323 their,optimum running behaviour is reached by a ratio of:

For bearings of series 313,having a largercontact angle,this ratio may be up to:

Especially in the case of a thrust loaded taper roller bearing arrangement it must beconsidered that the unloading of one of the bearings due to high axial loads may cause high sliding friction

in the bearings and thus generate high running noise and excessive wear,particularly in the cage pockets.

Equivalent static bearing load

For single row taper roller bearings:

P₀=0,5·F,+Y 。·Fa

When P 。is smaller than F,the F,value must be used for calculating the equivalent static bearing load.

Abutment and fillet dimensions

With taper roller bearings,a sufficient support of the bearing rings by the adjacent parts is required.

To gain satisfactory support both the shaft shoulders as well as the housing shoulders must have sufficient height.

The bearing rings,however,must contact adjacent parts with their side faces only.

The bearing chamfers must not contact the shoulder fillet radii of shaft or housing shoulders.

Therefore,the largest fllet radius(r or rg₁ , respectively)must be kept smaller than the minimum fillet dimension of the bearing rings(rs) as listed in the bearing tables.

Recommendations for the dimensions of adjacent parts are given in DIN 5418(Mounting dimensions of rolling bearings),as well as in the bearing tables

Supplementary designations

The product tables show the standardized bea- ring configurations updated on the edition of this catalogue.These standardized configurations co- rrespond to suffix or suffixes of each bearing.

In any case,VEO can offer,under requirement, alternative designs,comprising the ones showed in the following table or many others,whose mention exceeds the purpose of the present ca-

talogue,and can be found in specific technical publications of concrete applications or series of specific bearings.

Should you need a special design not existent in these pages,please contact our Sales Department in VEO Bearings Europe.

|

Suffix |

Description |

|

(J) |

Pressed window-type steel cage.No suffixas standard onVEO tapered roller bearings |

|

TVP |

Injection moulded window-type cage of glass fibre reinforced polyamide 6,6,rollercentred |

|

X |

Boundary dimensions changed to conform to ISO |

|

B |

Steeper contact angle thanstandard design |

|

R |

Integrated flanged outer ring(Fig.3) |

|

P6 |

Dimensional and running accuracy to old /SO tolerance class 6,better than Norma/ |

|

ENH |

Diynamic load rating for CrE*values of the product table |

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS