HOT PRODUCTS

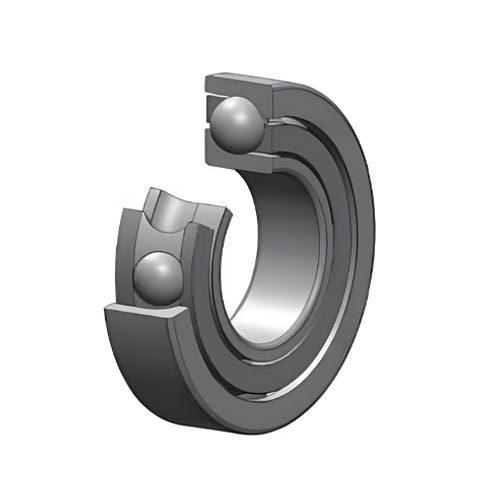

Thanks to its design with a split inner ring game these allow the incorporation of larger and more number of balls,providing a higher load capacity, in less space than a double row thrust bearings.

Cylindrical roller thrust bearingsare insensitive to shock loading and feature much higher load carrying capacity compared to thrust ball bea- rings.They accommodate very high axial loads but no radial forces.They provide a very rigid bearing assembly for highthrust loading with less space requirement.

The facility of mounting these bearing types using adapter and extraction sleeves enables mounting directly onto drawn or fine turned seats of shaft for applications where high running accuracy is not necessary.

Needle roller bearings with machined rings are usually of single -row design with the exception of bearings of the series NA69 or RNA69 respec- tively,which are produced in double row design from a specific size onwards.

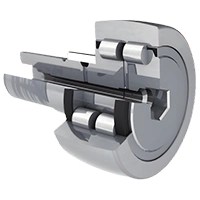

However,cam followers with cylindrical(flat) running surfaces are available for certain appli- cations.Instead of an inner ring,cam followers have a solid stud(pin)that is threaded so that the cam follower can be quickly and easily attached to appropriate machine components by means of a hexagonal nut.

These double row bearings can support heavier loads than the single row ones,with superior load capacity and therefore there are appropriate to replace the single row when the load ishigh.

They are used as non-locating bearings in bearing arrangements of machine tool spindles.Therefo- re,these bearings are normally used in high pre- cision tolerance class,frequently in combination with reduced internal clearance.

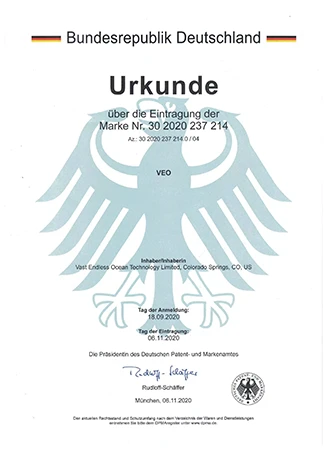

VEO Bearings Europe

VEO Bearings Europe was set up as an ambitious project more than a decade ago.The purpose was to become a reliable choice to the most prestigious traditional european manufacturers.Nowadays, we are established in more than 50 countries worldwide, and the number of companies that rely on us increases every day, and we are a solid alternative to the traditional European, USA, or Japanese Premium Class manufacturers.Our philosophy of continuous improvement has created the optimum choice for customers seeking premium quality products and flexible solutions for standard products and tailor made bearings. In order to provide full technical assistance to our customers, VEO offers an outstandingsupport by our Engineering Department.We design and produce a wide range of products in accordance with the highest european quality standards.

Factory covers an area

Annual sales volume

Number of factory employees

Export -countries and regions

Customer visit

BLOG

31

24/12

Which is better, cylindrical bearing or ball bearing

31

24/12

The structure of bearings mainly includes the following parts:

31

24/12

What are the functions of adding shaft sleeves between bearings

31

24/12

What is the purpose of bearings

31

24/12

Working principle of bearing production line

31

24/12

Advantages and disadvantages of needle roller bearings