7...-B-M

Category:

Single row angular contact ball bearings

Chat with us now for a quick response.

Keyword:

7...-B-M

PRODUCT DETAILS

Technical characteristics

Single row angular contact ball Bearings are non- separable,rigid radial bearings.

They consist of an inner ring and outer ring with a big and a small flange,so they can accommodate a large number of balls getting a relatively high load capacities.

Single row angular contact ball bearings are sui- table to support both axial and radial forces,in- cluding combined loads and tilting moments as well as being suitable for high speeds.As these

bearings only support axial loads in one direc- tion,they must be mounted in pairs against each other so each bearing will support the axial load in each direction.

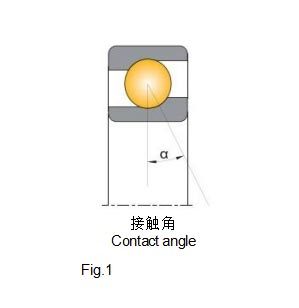

Single row angular contact ball bearings transfer the loads acting on the bearing with an angle, called the contact angle (a)(Fig.1).

The capacity of single row angular contact ball Bearings for supporting axial loads depends on their contact angle.The wider the angle,the hig- her the axial load capacity.

Usually the contact angle of these bearings is 40 degrees.This is indicated by the B suffix.

Their main dimensions are standardized in DIN 616 and DIN 628.

Standard design variants

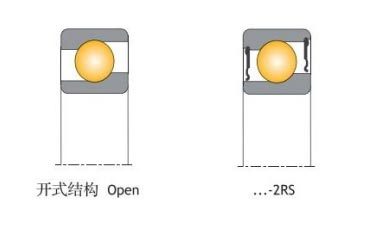

VEO single row angular contact ball bearings are available in a wide range of standardized designs (see Fig.2).

The standard range includes series 72..-B and 73..-B,which are divided into two designs,the basicone anda design for universal matching.

The VEO single row angular contact ball bearings with basic design,have normal tolerances in the flanges of the rings and in the bearing width.This feature does not allow

matching the standard bearings in pairs directly.

VEO single row angular contact ball bearings for universal matching,have different suffixes (see page 103 suffix table)depending on the special needs,are arranged in

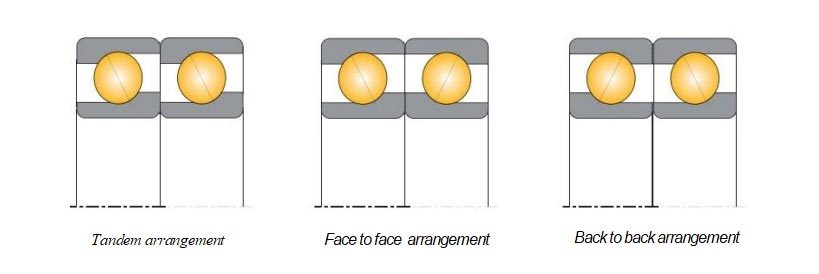

tandem(DT),face to face(DF)or back to back (DB).Due to their design,these bearings can be mounted in any arrangement without distinction.

These paired bearings are used in cases where the load capacity of a single bearing does not meet the requirements of the application.

It must be indicated the total number of indivi- dual bearings when ordering.

Arrangements

Tandem arrangement,suffix DT

This arrangement is used when the axial load ex- ceeds the axial load capacity of a single bearing. Thus,this load,as well as the radial load,are going to be divided equally between each of the

bearings.In case that there is an axial load in the opposite direction,these bearings should always be mounted with another bearing what supports the axial loads in the other direction.

Face to face arrangement,suffix DF

In this layout, the axial force is applied in both directions, and each direction is supported by a pairing bearing. The load line is collected towards the bearing axis. Because of its low rigidity, this

layout is not suitable for the loading torque. On the other hand, this layout does not require the middle and back to lay out as precise.

Back to back arrangement,suffix DB

In this arrangement,the axial forces are applied in both directions and each direction is suppor- ted by one of the paired bearings.Load lines diverge towards the bearing axis,which makes this

arrangement adequate for supporting tilting moments,being a relatively rigid arrangement. However,they are not valid to accommodate mi- salignments.

Misalignment

Due to their internal geometry,the auto align- ment capacity of single row angular contact ball bearings is reduced;therefore,the supports should be properly aligned.

Misalignment errors must be taken in mind,as these lead to an inappropriate ball rolling causing important additional forces that shorten life and generate higher levels of noise

The permissible angular misalignment between the inner and outer rings depend on:the size of the bearing,design,loads,bearing radial clea- rance,etc.Due to the complex

relationship bet- ween these factors and others,it cannot be given specific values.The customer must take special care when mounting the bearings.

It has been proven that in the face to face arran- gement with preload it is permissible up to two minutes of arc of misalignment from the middle position without significantly affecting

the per- formance of the bearings.

Tolerances

VEO single row angular contact ball bearings with basic design are made with normal tolerance class (PN)as standard.However,the bearings for universal matching are manufactured with tighter

tolerances than the normal class.

In applications where the precision is essential, VEO can supply,on request,single row angular contact ball bearings with tighter tolerances (P6, P5,P4 and P2).

The tolerances for these bearings are according to IS0492:2002 and are shown inthe corresponding tables displayed in the Introduction chapter.

Cages

VEO single row angular contact ball bearings are fitted with different types of cage and materials depending on their size and series.

There are different models of cages with diffe- rent characteristics,both in material and shape, depending on the application of the bearing. Some of those cages and their characteristics are

described below:

·J:Pressed window-type steel cage,ball cen- tred

·M:machined window-type brass cage,balls centred

·MB:Machined brass cage,inner ring centred

·TVP:Window-type glass fiber reinforced polya- mide cage,ball centred

Lubrication

VEO single row angular contact ball bearings with lip seals on both sides (suffix 2RS)are lubrica- ted forbearing life as standard with high quality grease.

VEO single row angular contact ball bearings in the designs opened and sealed only in oneside,can be lubricated with grease or oil once assembled, but they come as standard without

lubrication, only with an anti-rust protective lubricant.

As in other type of bearings,for the optimum performance,it should be provided the correct lubricant in the correct quantity.Currently,VEO has in its standard production range different ty- pes

of lubricants that can meet the requirements in the different operating conditions,e.g.:

-Grease with lithium thickener NLGI 2:tempera- tures -50 to+140°C

-Grease with lithium thickener NLGI 2:tempera- tures -50 to +90°C

-Grease with polyurea thickener NLGI 2:tempe- ratures -30 to +150°C

-Grease with polyurea thickener NLGI 2:tempe- ratures -40 to +150°C

In case of doubt,please,contact the VEO Applica- tions Engineering department.

In addition,VEO sealed single row angularcontact ball bearings can also be supplied on request with any other grease that meets the conditions requi- red by the customer.

Axial clearance and/or preload

The axial clearance and preload of the VEO sin- gle row angular contact ball bearings matched in pairs is achieved during the assembly,setting each bearing against the other.These bearings,

when they are intended for fitting in pairs,are identified with the suffixes UA,UL,UO,which appear in sufix table of this chapter (table 3).

VEO single row angular contact ball bearings are manufactured as standard with three types of internal clearance and/or preload.These types and their values are shown in the following table

(table 1).Those values are applicable to bearings before mounting or without applied loads,and are valid for bearings matched face to face and back to back.

VEO single row angular contact ball bearings can be supplied on request in other tolerance groups.

Note:for rigid fits,the axial internal clearance is reduced and /or the preload increases

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS