3 -- DB

Category:

Paired single row taper roller bearings

Chat with us now for a quick response.

Keyword:

3 -- DB

PRODUCT DETAILS

Technical characteristics

Paired taper roller bearings are used where ei- ther the load capacity of single bearings does not meet the requirements,or to overcome the time consuming adjustment under the conditions of a mass mounting.

Paired taper roller bearings consist of two mat- ched single row taper roller bearings using spa- cers for a specific axial clearance or a preload.

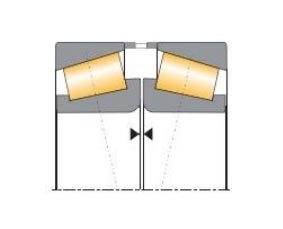

Depending on the particular requirements,such pairs may be supplied arranged either in tandem arrangement (suffix DT),in face to face arrange- ment (suffix DF),or in back to back arrangement

(suffix DB)as shown in the sketch below.

Other arrangements are produced upon order re- quest.

Bearing pairs

Tandem arrangement,suffix DT

Bearings in tandem arrangements are used where the actual thrust force exceeds the load capacity of a single bearing.

In tandem arrangements the thrust forces are ac- commodated in one direction only and distribu- ted to both bearings equally.

Taper roller bearings in tandem arrangement can only accommodate axial loads acting in one direction,therefore they should be mounted against other bearing that supports axial loads in the opposite direction

In tandem arrangement,taper roller bearings re- quire two spacers for matching as a unit,hence the desired total width of the bearing arrange- ment mustbe defined when

ordering.

Face to face arrangement,suffix DF

Thrust forces are accommodated in both direc- tions and in each direction forces are supported by one of matched the tapered roller bearings.

In taper roller bearings arranged face to face, the load lines converge towards the axis of the bearings,which makes these arrangements less suitable to support tilting

moments due to their lower stiffness

Attention: for bearingpairs arranged face to face the heating of the shaft will cause either a reduc- tion of axial internal clearance or an increase in preloading forces.

Back to back arrangement,suffix DB

Thrust forces are accommodated in both direc- tions and in each direction forces are supported by one of matched the tapered roller bearings.

Bearings arranged back to back provide very ri- gid bearing arrangements.They also effectively support tilting moments because the load lines diverge towards the bearing axis of the

bearings.

Taper roller bearing pairs arranged back to back require two spacers for matching as a unit,the desired total width of bearing arrangement must be defined at ordering.

Misalignment

Generally,taper roller bearings arranged in pairs should not be exposed to misalignments as they may generate considerable additional forces cau- sing high running noise levels.If those

misalign- ments can not be avoided,VEO recommends using the face to face arrangement,due to the lower rigidity of this disposition.

Such additional forces due to misalignment will shorten the service life of taper roller bearings significantly.

Tolerances

Paired VEO taper roller bearings are produced in normal tolerance class (PN)as standard.

These VEO bearings can be produced with closer tolerances according to customer requirements.

The total width tolerance of VEO-taper roller bearing units arranged face to face consist of the internal axial play of the bearing pair and twice the width deviation of the each single bearing,

Cages

VEOtaper roller bearings are fitted with pressed steel cages as standard.

Because the cages of taper roller bearings usually protrude beyond the bearing faces,special care must be taken to follow the recommended abutment dimensions.

Internal clearance

VEO taper roller bearing pairs arranged face to face (suffix DF)are standard produced with axial internal clearances values,as listed in thetable below.

When we indicate the suffix C..(special clearan- ce),the two or three-figure number immediately following the Cgives themean axial internal clea- rance in μm.This indicates that the

clearance is -30/+30 μm of this number,eg.,C200 indicates an axial clearance between 170 μm and 230 μm.

VEO also produces other bearing units with alter- native internal clearances according to customer's specifications on request.

Veo in the face layout becomes a shaft internal gap of the axial direction of the cone roller bearings

|

Axial interna/ clearance |

Bore diameter(mm) |

|||||||||

|

|

- |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

|

|

≤ |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

|

|

303..DF 322..DF |

min |

100 |

120 |

140 |

160 |

180 |

210 |

220 |

240 |

270 |

|

max |

140 |

160 |

180 |

200 |

220 |

270 |

280 |

300 |

330 |

|

|

313..DF |

min |

60 |

70 |

80 |

100 |

110 |

110 |

130 |

160 |

180 |

|

max |

100 |

110 |

120 |

140 |

170 |

170 |

190 |

220 |

240 |

|

Minimum load

For effective operation of taper roller bearings a minimum bearing load of approximately 2%of the dynamic load rating Cr is required.

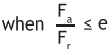

Equivalent dynamic bearing load

In the case of single row taper roller bearing pairs arranged face to face the following formula should be used:

then:P=F,+Y₁·Fa

then:P=F,+Y₁·Fa

or when  then:P=0,67·F,+Y₂·F

then:P=0,67·F,+Y₂·F

F₂and F,indicate the forces acting on the bearing pairs.

Equivalent static bearing load

When single row taper roller bearings are arran- ged in pairs face to face the equivalent static load on the bearing unit is:

Po 。=F,+Y₀·F

Abutment and fillet dimensions

Paired single row taper roller bearings must be supported axially by surrounding machine com- ponents in a satisfactory manner.

The bearing rings,however,must contact adja- cent parts with their side faces only.

The bearing chamfers must not contact the shoul- der fillet radii of shaft or housing shoulders.

Therefore,the largest fillet radius(rg)must be kept smaller than the minimum fillet dimension of the bearing rings(rs)as listed in the bearing tables

Recommendations for the dimensions of adjacent parts are given in DIN 5418(Mounting dimensions of rolling bearings),as well as in the bearing ta- bles.

Supplementary designations

The product tables show the standardized bea- ring configurations updated on the edition of this catalogue.These standardized configurations co- rrespond to suffix or suffixes of

each bearing.

In any case,VEO can offer,under requirement, alternative designs,comprising the ones showed in the following table or many others,whose mention exceeds the purpose of

the present ca- talogue,and can be found in specific technical publications of concrete applications or series of specific bearings.

Should you need a special design not existent in these pages,please contactour Sales Department in VEO Bearings Europe.

|

Suffix |

Description |

|

(J) |

Pressed window-type steel cage.No suffix as standard on tapered roller bearings VEO |

|

DB |

Matched bearing pair arranged back-to-back |

|

DF |

Matched bearing pair arranged face-to-face |

|

DT |

Matched bearing pair arranged in tandem |

|

C.. |

Special clearance.The two or three-figure number immediately following the Cgives the mean axial internal clearance in μm |

|

P6 |

Dimensional and running accuracy to old /SO tolerance class 6,betterthan Normal |

|

T.. |

The number inmediately following T gives the total width of bearingpairs arranged back-to- back or in tandem |

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS