3...-TVH

Category:

Double row angular contact ball bearings

Chat with us now for a quick response.

Keyword:

3...-TVH

PRODUCT DETAILS

Technical characteristics

VEO double row angular contact ball bearings are similar intheir internal structure to them paired single row angular contact ball bearings in back to back arrangement,but they are rigidly mat-

ched and they take axially less space.

These double row bearings can withstand higher radial and axial loads in both directions.They are suitable for applications that require rigid arran- gements in order to support tilting moments.

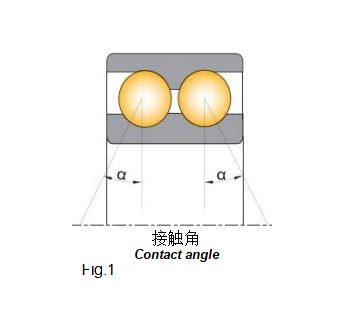

Double row angular contact ball bearings,as well as single row angular contact ball bearings,trans- fer the loads acting on the bearing with anangle, called the contact angle (a)(see Fig.1).

The capacity of double row angular contact ball bearings for supporting axial loads depends on their contact angle.The wider the angle,the hig- her the axial load capacity.

Their main dimensions are standardized in DIN 616 and DIN 628.

Standard design variants

VEO double row angular contact ball bearings are available in a wide range of standardized designs (see Fig.2).

The VEO standard range has the following types of double row angular contact ball bearings:

Basic design bearings

Sealed suffixes ,2RS or 2Z

Bearing with two-pieces inner ring,DA suffix

Basic design (32 and 33 series)

This bearing design is the most widely used wi- thin this type of bearings.They do not have fi- lling slots,so they can support higher radial and axial loads in both directions,as

well as their operation is more silent.VEO double row angu - lar contact ball bearings can be supplied,under request,with different angles of contact,if the application requires it.

52 and 53 series:bearings for the American mar -ket;These bearings (also sealed)have the same dimensions and characteristics as the series 32 rings that incorporate

special grease for hightemperatures.

Sealed bearings

Double row angular contact ball bearings can be supplied with seals or shields.Sealed design is lubricated with high quality grease and they are maintenance free (lubricated for

life).Bearings with shields are supplied with sheet steel plates on both sides of the bearing and like the previous type are greased for life.Grease maybe lost from

sealed bearings under extreme operating con- ditions like high speeds or temperatures,hence their speed will be lower than the speed of the unsealed.

Bearings with two pieces inner ring,suffix DA

These bearingshave inner ring divided in two pie- ces,which can be dismounted.They incorporate a larger number of larger balls and their contact angle is wider,thus,their axial loadcarrying ca-

pacity is higher in both directions,but specially in the axial direction.

Misalignment

Due to their internal geometry,the auto align- ment capacity of double row angular contact ball bearings is not allowed.

Misalignment errors must betaken into account, as these lead into an inappropriate rolling of balls,causing significant additional loads that shorten life and generate higher noise levels.

Tolerances

VEO double row angular contact ball bearings with basic design are made with normal tolerance class (PN)as standard.

In applications where the precision isessential, VEO can supply,on request,double row angular contact ball bearings with tighter tolerances (P6, P5,P4 and P2).

Cages

VEO double row angular contact ball bearings are fitted with different types of cages made with different materials depending on their size and series

Internal clearance

VEO double row angular contact ball bearings are manufactured with normalaxial internal clearan- ce.

VEO can supply on request with C3 clearance, greater than the normal clearance,or with C2 clearance,lower than the normal clearance.

The clearance values are shown in table 1.These values are relative to bearings before mounting and without loads.

Internal axial clearance groups of VEO double row angular contact ball bearings in

|

Clearance group |

Bore diameter(mm) |

|||||||||||

|

|

0 |

10 |

18 |

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

|

|

|

10 |

18 |

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

|

|

C2 |

min |

1 |

|

2 |

2 |

2 |

2 |

3 |

3 |

3 |

4 |

4 |

|

max |

11 |

12 |

14 |

15 |

16 |

18 |

22 |

24 |

26 |

30 |

34 |

|

|

CN |

min |

5 |

6 |

7 |

8 |

9 |

11 |

13 |

15 |

18 |

22 |

25 |

|

max |

21 |

23 |

25 |

27 |

29 |

33 |

36 |

40 |

48 |

53 |

59 |

|

|

C3 |

min |

12 |

13 |

16 |

18 |

21 |

23 |

26 |

30 |

35 |

42 |

48 |

|

max |

28 |

31 |

34 |

37 |

40 |

44 |

48 |

54 |

63 |

73 |

82 |

|

|

C4 |

min |

25 |

27 |

28 |

30 |

33 |

36 |

40 |

46 |

55 |

65 |

74 |

|

max |

45 |

47 |

48 |

50 |

54 |

58 |

63 |

71 |

83 |

96 |

108 |

|

Minimum load

For the correct performance of VEO double row angular contact ball bearings,it is needed a mi- nimum radial load.This minimum load will be es- sential in applications where speed is high,if

the- re will be sudden changes in acceleration,or if there is rapid changes in the direction of loads.

The minimum radial loadfor bearings with basic design,sealed or with two-pieces innerring must be at least 1%of the dynamic load C.

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS