QJ...-TVP

Category:

Four point contact ball bearings

Chat with us now for a quick response.

Keyword:

QJ...-TVP

PRODUCT DETAILS

Technical characteristics

The four point contact ball bearings can befitted within the single row angular contact ball bea- rings.

Four point contact bearings are suitable to su- pport high axial loads in both directions and they can also support some radial load if this does not exceed a certain value relative to the

axial load applied.

They consist of a solid outer ring and split inner ring into two symmetrical parts.

Thanks to its design with a split inner ring game these allow the incorporation of larger and more number of balls,providing a higher load capacity, in less space than a double row thrust

bearings.

Four point contact bearing VEO,are manufactu- red with a contact angle of 35 degrees.

These bearings can support high rotational speeds,in the case where they are only subject to purely axial loads.

Theirs main dimensions are standardized in DIN 628-4.

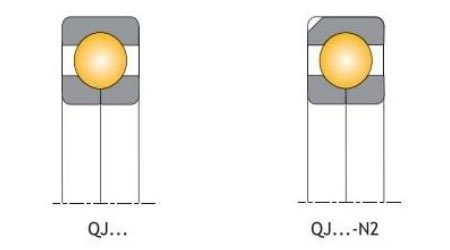

Standard design variants

Four point contact bearings are available in two basic standardized designs,with and without lo- catingslots in the outer ring.

Four point contact bearing with locating slots in the outer ring,are often used to support only axial loads,in this case,there will be radial clea- rance between the outer ring and the housing.So

for a correct and secure location,these bearings will be available with two locating slots.These slots are located at 180°and are identified with the suffix -N2.

The VEO standard range comprises QJ2 and QJ3 series.

Misalignment

Due to the geometry of the four point contact bearings,the capacity of accommodating self- alignment is very limited,therefore,supports should be properly aligned.

Misalignment errors must be taken in mind,as these errors lead to an inappropriate rolling of the balls,causes significant additional forces,re- duces the bearing service life and generates in-

creased noise levels.

The permissible angular misalignment between the inner and outer rings depend on:the size of the bearing,design,applied forces,bearing's ra- dial clearance...Remember that this capacity is

very limited.

Tolerances

VEO four point contact bearings,are manufactured with normal tolerance class (PN)as standard.

In some sizes or on request,in applications whe- re accuracy is critical,VEO can supply four point contact bearings with tighter tolerances (class P6).

The tolerances for these bearings are according to ISO 492:2002 and are shown in corresponding tables displayed in the Introduction chapter.

Cages

VEO four point contact bearings are equipped with one of the following types as standard,with different characteristics on material and shape depending on the application where the bearing

goes.These cages and their characteristics are described below:

MPA:machined brass cage,outer ring centered.

TVP:glass fiber reinforced polyamide cage (bearings with TVP cage are suita- ble for temperatures up to 120°C).

Seals

VEO four point contact bearings VEO are not sea- led.

Internal clearance

VEO four point contact bearings are manufactured as standard with normal axial internal clearance (CN).

In some sizes or on request VEO four point contact bearing are also available with reduced clearance limits.

The clearance values (valid for bearings before mounting)are shown in table 1 and are standar- dized in DIN 628-4.

Internal axial clearance groups of VEO four point contact ball bearings

|

Clearance group |

Bore diameter (mm) |

||||||||

|

> |

18 |

40 |

60 |

80 |

100 |

140 |

180 |

220 |

|

|

|

40 |

60 |

80 |

100 |

140 |

180 |

220 |

260 |

|

|

C2 |

min |

30 |

40 |

50 |

60 |

70 |

80 |

100 |

120 |

|

max |

70 |

90 |

100 |

120 |

140 |

160 |

180 |

200 |

|

|

CN |

min |

60 |

80 |

90 |

100 |

120 |

140 |

160 |

180 |

|

max |

110 |

130 |

140 |

160 |

180 |

200 |

220 |

240 |

|

|

C3 |

min |

100 |

120 |

130 |

140 |

160 |

180 |

200 |

220 |

|

max |

150 |

170 |

180 |

200 |

220 |

240 |

260 |

300 |

|

|

C4 |

min |

140 |

160 |

170 |

180 |

200 |

220 |

240 |

280 |

|

max |

190 |

210 |

220 |

240 |

260 |

280 |

300 |

360 |

|

Minimum axial load

For the correct operation of VEO four point contact bearing a need a minimum load is needed,as in other ball bearing types.The minimum axial load will be essential in high speed applications

(since the centrifugalforce becomes important),if they will be sudden changes in acceleration,or ifthere are sudden changes in direction of the loads.

This axial load must be at least high enough to ensure that all the balls are in contact with the raceways to prevent sliding damage.To achieve this minimal axial load the following formula is

applied:

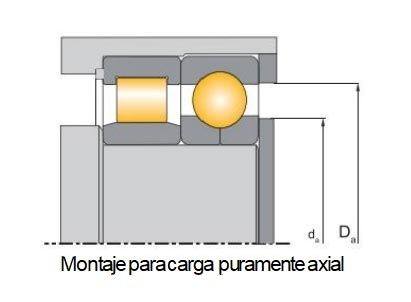

Note:If these bearings are to be used as purely axial bearings,ie the bearing is not charged with any radial load.Then,there must be enough radial clearance between the outer ring and the

housing to avoid the bearing supports radial loads (see Fig.2).

Supplementary designations

The product tables show the standardized bea- ring configurations updated on the edition of this catalogue.These standardized configurations co- rrespond to suffix or suffixes of each bearing

(see table 3)

In any case,VEO can offer,under requirement, alternative designs,comprising the ones showed in the following table or many others,whose mention exceeds the purpose of the present ca-

talogue,and can be found in specific technical publications of concrete applications or series of specific bearings.

Should you need a special design not existent in these pages,please contact our Sales Department in VEO Bearings Europe.

|

Suffix |

Description |

|

C3 |

Axial internal clearance larger than normal |

|

N2 |

Two locating slots (notches),180°apart,in the large outer ring side face |

|

TVP |

Window-type glass fiber reinforced polyamide cage, ball centred |

|

MPA |

Machined window-type brass cage,outer ring centred |

|

S1 |

Bearing rings dimensionally stabilized for use at operating temperatures up to +200℃ |

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS