NNF-PP-V

Category:

Double row full complement cylindrical roller bearings for cable sheaves

Chat with us now for a quick response.

Keyword:

NNF-PP-V

PRODUCT DETAILS

Technical characteristics

NNF50-PP-V type full complement bearings have a two piece inner ring having three integral flan- ges which is held together by a retaining ring for ease of handling and mounting.The outer ring features an integral centre flange.

These bearings are being produced with two con- tacting seals as standard.

These bearings are being preferably used as rope pulley bearings for cranes and hoisting equip- ment.NNF50-PP-V type bearings are beingsatis- factory in supporting high radial loads and axial forces acting in both directions.Due to their in- ternal geometry,they can also accommodate til- ting moments.

As these bearings are being primarily used as rope sheave bearings,they have an outer ring that is 1 mm less wide than the inner rings.This speci- fic feature allows omitting additional sleeves

or washers.

As a standard feature,NNF50-PP-V type full com- plement bearings have two retaining ring grooves in their outer ring.

This feature allows for a simple and cost effec- tive method of mounting rope pulleys,etc.by using snap rings.

As NNF50-PP-V type bearings are standard fitted with two contacting seals they are supplied grea- se filled by the factory with a high quality bearing grease.

Bearings of the series NNF50-PP-V operating at high speeds or under harsh conditions (e.g.the presence of saltwater,high humidity,contamina- tes etc.)require more frequent lubrication.

To allow for simple relubrication,the bearings are standard manufactured with two independent working relubrication possibilities;these bearings can get lubricated via lubricating grooves and

bores in the inner rings or,alternatively,via the lubrication groove and holes into the outer ring.

Appropriate snap rings

As a standard feature,NNF50-PP-V type full com- plement bearings have two retaining ring grooves in their outer ring for a simple andcost effective method of mounting rope pulleys,etc.by

using WRE and WR type snap rings or standard snap rings according to DIN471.

These snap rings are being not supplied withthe bearings.

PP Sealing

NNF50-PP-V bearings have contacting seals fitted to either side of the bearing as standard these seals are made from specifically resistant Polyu- rethane.The seals are mounted on the inner

ring shoulders and contact the outer ring raceway with light preload on the sealing lip.

These seals provide an efficient sealing against dust,contamination and splash water or water spray.

NNF50-PP-V can be supplied with different spe- cial seals or metal shields on order request.

Anti corrosion coating

VEONNF50-PP-V type full complement cylindrical roller bearings can be supplied with an effective anti rust protection,suffix CE05.

This coating allowsbearings to work even under aggressive environments,i.e.,salt water spray or dust.

Lubrication

When working under harsh conditions,such as the presence of salt water,high humidity contaminates etc.)or when operating at high speeds,these bearings require a more frequent re-

lubrication.Due to the specific design of the bearing,arelubrication can be performed either through the inner ring as well as via the outer ring.

When re-greasing NNF50-PP-V bearings,particu- lar care must be applied in order to prevent the seals from popping out of the bearings during re- greasing.

Following guidelines apply:

make sure that the correct grease type is being used

make sure that the grease is clean and free from any contamination

apply the grease slowly until the old grease is being squeezed out of the bearing

make sure that the seals are not getting squee- zed out by the grease pressure.If necessary, support the PP-seals with washers to prevent them from being squeezed out

If bearings with one or no seals are required,the seals may be removed easily by using a screw- driver.For applications where oil lubrication is used,the bearings can be delivered without seals

and grease if economic quantities are involved. Otherwise the seals should be removed and the bearings washed before use.If oil lubrication is used,the speed limits quoted in the product ta-

bles can be increased by approximately 30%.

VEO NNF50-PP-V cylindrical roller bearingscan be supplied with special grease (suffix -L02)for low temperatures (-54°C).

Misalignment

Double row full complement cylindrical roller bearings are not able to absorb a misalignement

Tolerances

VEO full complement cylindrical roller bearings areproduced to tolerance class PN as standard.

For obtaining detailed values on tolerances refer to the chapter Bearing data and Tolerances.

In case of bearings having anti corrosion coating, i.e.suffix CE05,the tolerances apply to the bearings in uncoated condition.

Internal radial clearance

VEO full complement cylindrical roller bearings are produced to normal internal clearance group (group CN)as standard.

VEO bearings can also be produced to other clea- rance groups to customers order.

The clearance values correspond,as far as they are standardized,to the relevant international standards DIN 620 part 4 and ISO5753-1991.

The values of the different internal clearance groups of seales,double row VEO cylindrical roller bearings for rope sheaves are listed in table 1(page 331).

Non-standardized internal clearance

VEO sealed,double row full complement cylindri- cal roller bearings for rope sheaves can also be

produced with individually defined special inter- nal clearances to customers order. This includes the possibility of producing bearings with a clearance restricted to a part of thefull clearance

range,i.e.C3H etc

VEO sealing full of cylindrical roller bearing for the VEO of the steel wire pulley

|

Clearance group |

Bore diameter(mm) |

||||||||||||||

|

> |

|

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

60 |

180 |

200 |

225 |

|

|

≤ |

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

225 |

250 |

|

|

C2 |

min |

0 |

0 |

5 |

5 |

10 |

10 |

15 |

15 |

15 |

20 |

25 |

35 |

45 |

45 |

|

max |

25 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

70 |

75 |

90 |

105 |

110 |

|

|

CN |

min |

20 |

20 |

25 |

30 |

40 |

40 |

50 |

50 |

60 |

70 |

75 |

90 |

105 |

110 |

|

max |

45 |

45 |

50 |

60 |

70 |

75 |

85 |

90 |

105 |

120 |

125 |

145 |

165 |

175 |

|

|

C3 |

min |

35 |

35 |

45 |

50 |

60 |

65 |

75 |

85 |

100 |

115 |

120 |

140 |

160 |

170 |

|

max |

60 |

60 |

70 |

80 |

90 |

100 |

110 |

125 |

145 |

165 |

170 |

195 |

220 |

235 |

|

|

C4 |

min |

50 |

50 |

60 |

70 |

80 |

90 |

105 |

125 |

145 |

165 |

170 |

195 |

220 |

235 |

|

max |

75 |

75 |

85 |

100 |

110 |

125 |

140 |

165 |

190 |

215 |

220 |

250 |

280 |

300 |

|

|

C5 |

min |

75 |

75 |

85 |

100 |

110 |

125 |

140 |

165 |

190 |

215 |

220 |

250 |

280 |

300 |

|

max |

100 |

100 |

110 |

130 |

140 |

160 |

175 |

205 |

235 |

265 |

270 |

305 |

340 |

365 |

|

|

Clearance group |

Bore diameter(mm) |

||||||||||||||

|

> |

250 |

280 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

710 |

800 |

|900 |

1.000 |

1.120 |

|

|

≤ |

280 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

710 |

800 |

900 |

1.000 |

1.120 |

1.250 |

|

|

C2 |

min |

55 |

55 |

65 |

100 |

110 |

110 |

120 |

140 |

145 |

150 |

180 |

200 |

220 |

230 |

|

max |

125 |

130 |

145 |

190 |

210 |

220 |

240 |

260 |

285 |

310 |

350 |

390 |

430 |

470 |

|

|

CN |

min |

125 |

130 |

145 |

190 |

210 |

220 |

240 |

260 |

285 |

310 |

350 |

390 |

430 |

470 |

|

max |

195 |

205 |

225 |

280 |

310 |

330 |

360 |

380 |

425 |

470 |

520 |

580 |

640 |

710 |

|

|

C3 |

min |

190 |

200 |

225 |

280 |

310 |

330 |

360 |

380 |

425 |

470 |

520 |

!580 |

640 |

710 |

|

max |

260 |

275 |

305 |

370 |

410 |

440 |

480 |

500 |

565 |

630 |

690 |

770 |

850 |

950 |

|

|

C4 |

min |

260 |

275 |

305 |

370 |

410 |

440 |

480 |

500 |

565 |

630 |

690 |

770 |

850 |

950 |

|

max |

330 |

350 |

385 |

460 |

510 |

550 |

600 |

620 |

705 |

790 |

860 |

960 |

1.060 |

1.190 |

|

|

C5 |

min |

330 |

350 |

385 |

460 |

510 |

550 |

600 |

620 |

705 |

790 |

860 |

960 |

1.060 |

1.510 |

|

max |

400 |

425 |

465 |

550 |

610 |

660 |

720 |

740 |

845 |

950 |

.030 |

1.150 |

1.270 |

1.750 |

|

Operating temperature

Restricted by the seal material and the grease, NNF50-PP-V bearings are suitable for operating temperatures from -20℃ to +80°C.

Under request,the bearings can be supplied with special seals (suffix -PS)to increase the maximum operating temperature to+120C and/ or with special grease (suffix-L02)for extreme

temperatures to decrease the lower limit to -54℃.

Minimum load

Rolling bearings require a sufficient minimum radial load to prevent excessive sliding friction. Particularly full complement cylindrical roller bearings require a minimum radial load of more

than 4%of the dynamic load rating Cr.

Dynamic axial load carrying capacity

NNF50-PP-V type full complement cylindrical ro- ller bearings are primarily designed to accommo- date radial loads.However,they are also suitable to accept thrust forces acting in one or both

di- rections to a limited extend.

Thrust forces applied to cylindrical roller bea- rings generate sliding friction between the roller end faces and the guiding flanges.

Hence,an optimum lubrication is crucial.Fur- thermore,every thrust load creates a tilting mo- ment on the rollers.

This requires an additional radial loading to ensu- re an effective function of the bearing.

For all these reasons together with the existence of grooves in the outer ring,in the case of cylindrical roller bearings with snap ring grooves application engineering advice is necessary

Please,consult VEO application engineering department when axial loads are expected.

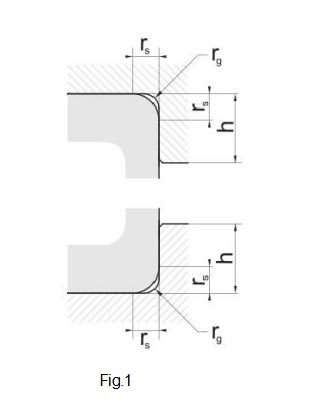

Abutment and fillet dimensions

The shoulders on adjacent machine parts must be designed in such a way that the required axial support of the bearing rings is guaranteed.

The bearing rings must contact adjacent parts with their side faces only.

The bearing chamfers must not contact the shoulder fillet radii of shaft or housing shoulders.

Therefore,the largest fillet radius(rg)must be kept smaller than the minimum chamfer on the bearing rings(rs)given in the product tables.

Recommendations for the dimensions of adjacent parts are given in DIN 5418.

|

rs Minimum |

rg Maximum |

h |

|

0,3 |

0,3 |

1 |

|

0,6 |

0,6 |

1,6 |

|

1 |

1 |

2,3 |

|

1,1 |

1 |

3 |

|

1,5 |

1,5 |

3,5 |

|

2 |

2 |

4,4 |

|

2,1 |

2,1 |

5,1 |

|

3 |

2,5 |

6,2 |

|

4 |

3 |

7,3 |

|

5 |

4 |

9 |

Supplementary designations

The product tables show the standardized bearing configurations updated on the edition of this catalogue.These standardized configurations correspond to suffix or suffixes of each bearing.

In any case,VEO can offer,under requirement, alternative designs,comprising the ones showed in the following table or many others,whose mention exceeds the purpose of the present

catalogue,and can be found in specific technical publications of concrete applications or series of specific bearings.

Should you need a special design not existent in these pages,please contact our Sales Department in VEO Bearings Europe.

|

Suffix |

Description |

|

C2 |

Radial internal clearance smaller than normal |

|

C3 |

Radial internal clearance larger thannorma/ |

|

C4 |

Radial internal clearance larger than C3 |

|

C5 |

Radial internalclearance larger than C4 |

|

PP |

Contact sealsof polyurethane onboth sides ofthe bearings |

|

V |

Full complement of rollers,without cage |

|

L01 |

Grease for low temperature,up to-54℃ |

|

L06 |

Specialgrease designed for applications where outstandingprotection against corrosion and wearis required |

|

PP1 |

Machined polyurethane contact seals to accept upto 4 bar of outer pressure |

|

PP2 |

Injected TPU contact seals for extremely humid andsalty environment.Added protection against UV rays |

|

PS |

Sheet steelshields |

|

CE03 |

Black oxide coated |

|

CE04 |

Phosphate coated |

|

CE05 |

Anti corrosion coating |

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE