NA48,NA49

Category:

Needle roller bearings without inner ring

Chat with us now for a quick response.

Keyword:

NA48,NA49

PRODUCT DETAILS

Technical Characteristics

Needle roller bearings are separable radial bea- rings.The use of needle rollers allow for low sec- tional heights in combination with high rigidity and excellent load carrying capability.

If needle roller bearings work in confined space (e.g.gear boxes),they may also be used without inner rings,designation(RNA).In these cases the needle rollers run directly on the shafts.

The running surfaces,however,must be hardened and ground to the same quality standard as for bearing raceways.

Since needle roller bearings areoptimum as non- locating bearings as they allow for length com- pensation within the bearing.

Forapplications where the non-locating bearings require bigger axial displacement,needle roller outer and cage assemblies can be combined with extra wide inner rings.

Standard design variants

Needle roller bearings with machined rings are available in different designs including variants with no inner rings.

The more important design variations are intro- duced on the following pages.

The bearing outer rings form a unit together with the needle roller set and cage.The outer rings have lips for guiding the bearing needles.

These are either integrated solid ribs,or in the case of small needle roller bearings,separate pressed in loose ribs

To allow for a simple relubrication,needle roller bearing outer rings with the exception of very small bearing rings (see c and e),are produced with a relubricating groove and lubricating

holes in their outer rings as standard features.

Needle roller bearings with machined rings are usually of single -row design with the exception of bearings of the series NA69 or RNA69 respec- tively,which are produced in double row

design from a specific size onwards.

Sealed needle roller bearings

Series NA48 and NA49 needle roller bearings are also available in sealed design,either as a single sealed (suffix RSR)or double sealed (suffix-2RSR) respectively.

These bearings are equipped with contacting seals made from wear-resistant synthetic nitrile rubber(NBR)this prevents contamination by fo- reign particles and impurities.

The seal material is suitable for operating tempera- tures of-30℃up to+120℃(-22°F up to +248°F).

Sealed needle roller bearings are supplied with a factory-applied grease filling with a high quali- ty bearing grease,for operating temperatures of -30℃up to+110°C(-22°F up to +230°F).

To ensure an optimum sealing performance even under large axial displacement the inner ring wi- dths of sealed needle roller bearings are,norma- lly,1 mm wider than the outer ring width.

The inner rings of sealed needle roller bearings do not have chamfered edges on their raceways.

In addition to the lubrication facilities on the outer ring,sealed needle roller bearings fre- quently have a lubricating hole in the bearing inner rings.

Misalignment

Due to the line contact between the needle ro- llers and the raceways,needle roller bearings ge- nerally have very low ability to compensate for misalignments

Despite the modified contact geometry of the needle rollers,used in VEO needle roller bearings, it is recommended any misalignment is avoided since even small misalignments may generate

ex- tra forces including running noise.

Also it must be considered that bearings running un- dermisalignments may have reduced service life.

Cages

VEO needle roller bearings are standard produced with pressed steel cages.

The exceptions are small needle roller bearingsha- ving solid polyamide cages as standard (suffixTVP).

Tolerances

VEO Needle roller bearings are produced to nor- mal tolerance (class PN)as standard.On request these bearings may also be produced with closer tolerance,(i.e.to tolerance class P6).

Normally the diameter under rollers,(FW)wi- thout inner rings (design RNA),correspond to the ISO tolerance field F6.

Internal radial clearance

VEO needle roller bearings are produced with nor- mal internal clearance group (CN)as standard.

VEO needleroller bearings can also be produced to other internalclearances groups on order re- quest,see tablesbelow.

These values conform,as far as they have been standardised,to both ISO 5753-1991and DIN 620/ part 4,respectively.

|

Clearance group |

Bore diameter(mm) |

|||||||||||||||||

|

> |

0 |

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

225 |

250 |

280 |

315 |

|

|

≤ |

24 |

30 |

40 |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

225 |

250 |

280 |

315 |

355 |

|

|

C2 |

min |

0 |

0 |

5 |

5 |

10 |

10 |

15 |

15 |

15 |

20 |

25 |

35 |

45 |

45 |

55 |

55 |

65 |

|

max |

25 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

70 |

75 |

90 |

105 |

110 |

1 125 |

130 |

145 |

|

|

CN |

min |

20 |

20 |

25 |

30 |

40 |

40 |

50 |

50 |

60 |

70 |

75 |

90 |

105 |

110 |

125 |

130 |

145 |

|

max |

45 |

45 |

50 |

60 |

70 |

75 |

85 |

90 |

105 |

120 |

125 |

145 |

165 |

175 |

195 |

205 |

225 |

|

|

C3 |

min |

35 |

35 |

45 |

50 |

60 |

65 |

75 |

85 |

100 |

115 |

120 |

140 |

160 |

170 |

190 |

200 |

225 |

|

max |

60 |

60 |

70 |

80 |

90 |

100 |

110 |

125 |

145 |

165 |

170 |

195 |

220 |

235 |

260 |

275 |

305 |

|

|

C4 |

min |

50 |

50 |

60 |

70 |

80 |

90 |

105 |

125 |

145 |

165 |

170 |

195 |

220 |

235 |

260 |

275 |

305 |

|

max |

70 |

75 |

85 |

100 |

110 |

125 |

140 |

165 |

190 |

215 |

220 |

250 |

280 |

300 |

330 |

350 |

385 |

|

Design of bearing raceways

If needle roller bearings are being used without inner rings,the needle rollers run directly onto the shaft surface.

Since this affected shaft area has to act as a bea- ring inner ring,certain minimum requirements for hardness,dimensional and geometric accura- cy must be fulfilled.

The operational clearance for needle roller bea- ring assemblies which run directly onto theshaft is determined by the tolerance field selected for an"actual"raceway.

In theory,however,for housing fits closer than K7 the actual operating clearance must be checked by actual measurement or calculation.Considera- tion must also be given to the

reduction in inter- nal radial clearance due to thermal expansion.

Minimum load

Needle roller bearings require a certain minimum load to perform correctly.

To prevent excessive sliding friction,the mini- mum load applied must be greater than 2%of the bearing dynamic load rating C

Equivalent dynamic bearing load

Needle roller bearings are pure non -locating bearings.They are unable to accommodate any thrust loads.

Therefore:

P=F,

Equivalent static bearing load

For needle roller bearings:

P₀=F,

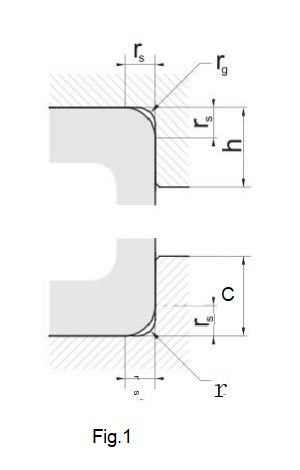

Abutmentand fillet dimensions

The bearing rings must contact adjacent parts with their side faces only.The radii of bearing corners must not touch the shoulder fillet radii of neither the shaft shoulders nor the housing.

Therefore,the largest fllet radius(rg)must be smaller than the minimum fillet dimension of the bearing rings(rs)as listed in the bearing tables (see details on the following page).

Recommendations for the dimensions of adjacent parts are given by DIN 5418.

|

rs min |

rg max |

hmin |

|

0,15 |

0,15 |

0,6 |

|

0,3 |

0,3 |

1 |

|

0,6 |

0,6 |

2 |

|

1 |

1 |

2,5 |

|

1,1 |

1 |

3,25 |

|

1,5 |

1,5 |

4 |

|

2 |

2 |

5 |

|

2,1 |

2,1 |

5,5 |

|

3 |

2,5 |

6 |

Needle roller bearing inner rings

Besides their original purpose,needle roller bea- ring inner rings are often used as a contact face for radial oil seals.

The hardened and fine ground ring raceways con- siderably improve the performance and service life of radial oil seals without the shaft having to be hardened and ground.

In the event of repairing or overhauling the ma- chine a simple exchange of the affected parts is sufficient whilst the shaft,however,may conti- nue to be used unaffected.

Design features of inner rings

VEO needle roller bearing inner rings are produ- ced from chromium bearing steel to DIN 17230, (SAE 52100)with normal tolerance class(PN)ac- cording to DIN 620.

The hardened rings feature superfinished ra- ceways.Normally,the tolerances for the raceway diameters F is defined in such a way that a nor- mal operating clearance (CN)results.

Design variants

VEO also produce separate needle roller bearing inner rings in various designs,(i.e.with pre- ground raceways only,with alternative dimen- sions,other tolerance classes or to customers

specifications).

FACTORY

Trade communication & visit

COMMON PROBLEM

GET A FREE QUOTE

RELATED PRODUCTS